- RESIDENTIAL CONSTRUCTION

- COMMERCIAL CONSTRUCTION

- HOME IMPROVEMENT

- Products

- Framing Lumber & Sheathing

- Exterior Siding

- Doors

- Molding

- Windows

- Drywall

- Roofing

- Insulation

- Roof Trusses

- Floor Trusses

- Engineered Wood Products

- Masonry & Concrete

- Decks

- Hand & Power Tools

- Hardware

- Paint & Stain

- Plumbing

- Heating & Cooling

- Lawn & Garden

- Lighting & Electrical

- Storage & Organization

- Kitchen Cabinets

- Flooring

- Fencing

- Mobile Home & RV Supply

- Services

- Home Inspiration

- Current Ads

- Build Rewards

- Service Directory

- Products

- REQUEST A QUOTE

- BLOG

- CONTACT

- ACCOUNT SETUP

- ABOUT

Top 10 Benefits of Prefabricated Wall System for Your Projects?

The construction industry is rapidly evolving, and the prefabricated wall system is at the forefront of this transformation. Recent reports highlight that prefabricated building methods can reduce construction time by up to 30%, significantly affecting project schedules. This approach not only streamlines the building process but also enhances overall efficiency.

Furthermore, studies reveal that using a prefabricated wall system can lead to reduced material waste, cutting disposal costs by approximately 20%. Builders are taking note of these benefits, as the growing focus on sustainability becomes a priority. Despite these advantages, some projects still shy away from prefabrication due to misconceptions about initial costs and logistical challenges.

As the industry matures, the adoption of a prefabricated wall system is becoming increasingly common. It allows for better quality control and can lower labor costs, yet it requires a cultural shift within traditional construction practices. There are still hurdles to overcome, such as designing systems compatible with various climates and architectural styles. Recognizing these strengths and weaknesses can help professionals make more informed decisions for their projects.

Benefits of Prefabricated Wall Systems in Modern Construction

Prefabricated wall systems are transforming construction. They offer numerous benefits that enhance efficiency and reduce costs. According to a recent report by McGraw Hill, projects using prefabricated systems can save up to 20% on overall build time.

One key advantage is improved quality control. Walls are built in a controlled environment, minimizing issues like weather delays or inconsistent craftsmanship. This leads to higher durability and less waste. A study by the National Institute of Standards and Technology found that utilizing prefabrication can decrease material waste by 30%, significantly benefiting the environment.

**Tip:** Consider integrating prefabricated wall systems early in your design process. This allows architects and builders to optimize their plans. Early collaboration fosters innovation and streamlines production.

While these systems are beneficial, challenges exist. Some might find it hard to adapt to the new technology or design considerations. It's essential to invest in training and education to overcome these hurdles. Long-term success relies on adjusting traditional practices to embrace modern solutions.

**Tip:** Regularly reassess the project needs. This ensures that the prefabricated approach aligns well with evolving design requirements. Staying flexible is key in today’s fast-paced construction landscape.

Top 10 Benefits of Prefabricated Wall System for Your Projects

| Benefit | Description | Impact on Project |

|---|---|---|

| Speed of Construction | Prefabricated walls are manufactured off-site, reducing overall construction time. | Accelerates project delivery, allowing for quicker occupancy. |

| Quality Control | Produced in a controlled environment, ensuring consistent quality. | Reduces the risk of defects and improves overall building quality. |

| Cost Efficiency | Lower labor costs and reduced material waste lead to overall savings. | Enhances the project's return on investment. |

| Energy Efficiency | Advanced insulation techniques used in panels improve energy performance. | Reduces utility costs and enhances sustainability. |

| Design Flexibility | Easily customizable to fit various design requirements. | Allows for creative architectural solutions. |

| Site Safety | Fewer workers on-site reduce the chance of accidents. | Improves overall safety and compliance with regulations. |

| Reduced Environmental Impact | Minimized waste during off-site construction processes. | Supports green building initiatives. |

| Improved Thermal Performance | Customized thermal insulation properties enhance comfort. | Results in a more pleasant indoor environment. |

| Shorter Schedule | Parallel construction processes for site work and wall assembly. | Helps keep the project timeline on track. |

| Enhanced Aesthetics | Various finishes can be applied before delivery. | Improves the visual appeal of the project. |

Enhanced Efficiency: Time Savings with Prefabrication

Prefabricated wall systems significantly enhance project efficiency. Traditional construction often leads to project delays. In contrast, prefabrication allows for simultaneous site preparation and wall assembly. According to a study by McGraw Hill, projects using prefabricated components saw time savings of up to 50%. This can be crucial for meeting tight deadlines.

Moreover, the reduced need for on-site labor makes prefabrication an attractive option. Fewer workers at the site mean less congestion and better focus on tasks. However, the upfront planning stage requires detailed coordination. Overlooking this can lead to inefficiencies down the line.

Tips: Regular communication with all stakeholders can streamline the process. Ensure that design specifications are clear to avoid costly revisions. A thorough review of the assembly process before installation can save time later.

Prefabrication does have its challenges. Transportation can sometimes delay delivery schedules. Furthermore, not all designs will fit seamlessly into prefabricated solutions. Care is essential in the early phases. Adapting designs to benefit from prefabrication is crucial for maximizing time savings.

Cost-Effectiveness: Reducing Overall Project Expenses

Cost-effectiveness is a critical factor in construction projects.

Prefabricated wall systems stand out in this regard. They simplify the building process, reducing labor costs significantly. Projects that use prefabricated walls often complete faster, which translates to lower overhead expenses. With less time on-site, there are fewer delays, saving money.

This method also minimizes waste. Traditional construction generates excess material that often ends up discarded. However, prefabrication allows for better planning. The components are made to exact specifications, reducing the chances of surplus. Yet, some projects may miscalculate needs, leading to shortages or delays. Adjusting to these challenges is essential for maximizing benefits.

Another financial advantage is the predictable pricing structure. Costs are established up front, aiding budget management. This predictability can help in securing financing. However, it's vital to ensure that all details are clear from the start. Miscommunication can lead to unexpected costs and complications later. Therefore, careful planning and open dialogue are key.

Improved Quality Control in Manufacturing Processes

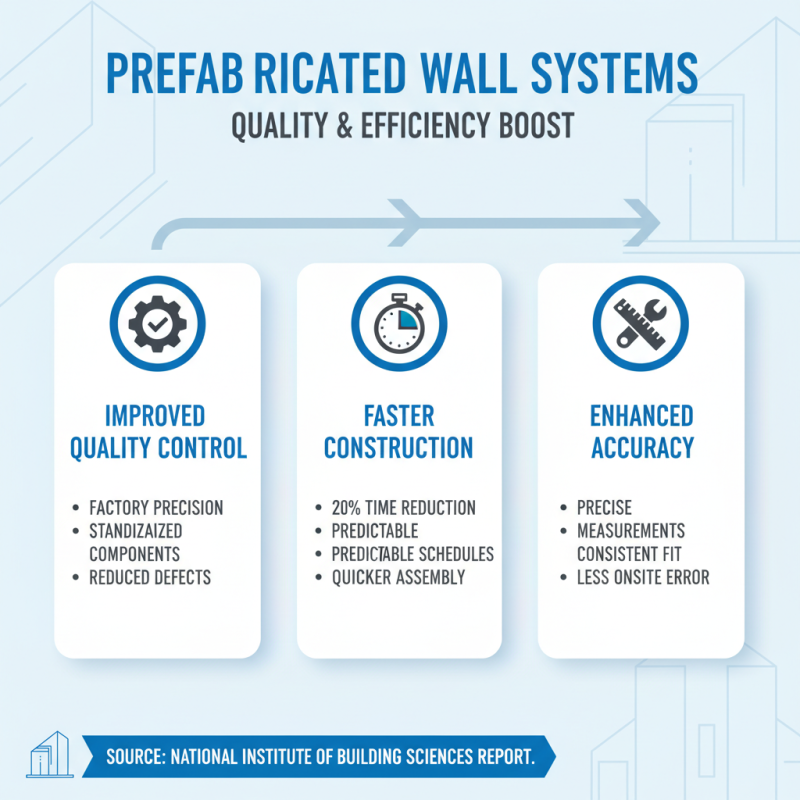

Prefabricated wall systems offer notable improvements in quality control during manufacturing processes. By utilizing advanced technology, manufacturers can create consistent and standardized components. This leads to a reduction in defects and enhances overall product quality. According to a report from the National Institute of Building Sciences, prefabrication can decrease construction time by 20% and enhance accuracy in building components.

Furthermore, controlled factory conditions allow for better oversight in production. This minimizes the impact of environmental factors that typically cause inconsistencies on-site. For instance, a study by McGraw Hill found that 74% of professionals cited improved quality as a primary benefit of prefabrication. This approach reduces waste and lowers costs, although initial investment in technology can be high.

Despite these advantages, challenges still remain. Some contractors find it difficult to adapt to this method. Training is needed for teams unfamiliar with off-site construction practices. Additionally, logistical issues can arise when transporting large components to job sites. Overall, while quality control in prefabricated systems shows promise, careful planning is essential for optimal implementation.

Flexibility and Design Versatility of Prefabricated Walls

Prefabricated walls offer remarkable flexibility and design versatility, making them a popular choice in modern construction projects. Architects and builders can easily customize these walls to fit various design aesthetics. Whether you envision a sleek, minimalist look or a more traditional style, prefabricated systems can adapt accordingly. This adaptability not only enhances aesthetic value but also allows for quicker modifications during the construction phase.

Additionally, the use of prefabricated wall systems can significantly reduce project timelines. These walls are constructed off-site, minimizing on-site labor and disruption. However, this approach requires careful planning. Design changes must be finalized early in the process to prevent costly delays. While the flexibility is an advantage, it can become a challenge when last-minute adjustments arise. Managing these aspects effectively is crucial to leveraging the full potential of prefabricated walls.

Conclusion

The article "Top 10 Benefits of Prefabricated Wall System for Your Projects" highlights the various advantages of using prefabricated wall systems in modern construction. These systems significantly enhance efficiency by reducing construction time, allowing for quicker project completion. Additionally, they offer cost-effectiveness by minimizing overall project expenses through streamlined processes and reduced labor costs.

Furthermore, prefabricated wall systems ensure improved quality control as they are manufactured in a controlled environment, leading to consistent product quality. They also provide design versatility, catering to various architectural styles and preferences. Lastly, the sustainability aspect emphasizes the eco-friendly nature of prefabricated systems, which contribute to reducing waste and promoting environmentally responsible construction practices. Overall, the integration of prefabricated wall systems represents a forward-thinking approach in the construction industry.

Related Posts

-

Top 10 Tips for Choosing Framing Lumber: A Complete Buying Guide

-

What Are Raised Wall Panels? Benefits, Types, and Installation Tips Explained

-

How to Choose the Best Pre Fab Walls for Your Construction Project

-

What is Flat Panel Wainscoting and How Can It Transform Your Home

-

The Ultimate Guide to Cedar Trusses Benefits and Applications

-

How to Choose the Right Decorative Trusses for Your Home Décor