- RESIDENTIAL CONSTRUCTION

- COMMERCIAL CONSTRUCTION

- HOME IMPROVEMENT

- Products

- Framing Lumber & Sheathing

- Exterior Siding

- Doors

- Molding

- Windows

- Drywall

- Roofing

- Insulation

- Roof Trusses

- Floor Trusses

- Engineered Wood Products

- Masonry & Concrete

- Decks

- Hand & Power Tools

- Hardware

- Paint & Stain

- Plumbing

- Heating & Cooling

- Lawn & Garden

- Lighting & Electrical

- Storage & Organization

- Kitchen Cabinets

- Flooring

- Fencing

- Mobile Home & RV Supply

- Services

- Home Inspiration

- Current Ads

- Build Rewards

- Service Directory

- Products

- REQUEST A QUOTE

- BLOG

- CONTACT

- ACCOUNT SETUP

- ABOUT

How to Choose the Best Pre Fab Walls for Your Construction Project

In today's fast-paced construction industry, choosing the right materials is crucial for the efficiency and sustainability of any project. Pre fab walls, also known as prefabricated walls, have become increasingly popular due to their ability to significantly reduce construction time and costs. According to a report by the National Institute of Building Sciences, projects utilizing pre fab walls can see installation time reduced by up to 50%, leading to quicker project completion and lower labor expenses. As the demand for rapid and efficient building solutions rises, understanding how to select the best pre fab walls tailored to your needs is essential.

Industry expert John Moore, a leading architect with over 20 years of experience in prefabricated construction, emphasizes the importance of optimizing wall selection, stating, “The long-term success of a project hinges on the careful choice of construction materials, particularly pre fab walls, which can directly influence both energy efficiency and structural integrity.” This highlights the need for stakeholders to be educated about the various options available in the market, ensuring that the chosen pre fab walls not only align with the project’s requirements but also contribute to sustainability goals.

Ultimately, the decision-making process surrounding pre fab walls involves evaluating factors such as material composition, energy efficiency, and design flexibility. By understanding these aspects, construction professionals can make informed choices that enhance the overall quality and performance of their projects while leveraging the benefits that pre fab walls offer.

Understanding Prefabricated Walls: Definition and Benefits

Prefabricated walls are an innovative solution gaining traction in the construction industry, defined as building components manufactured off-site and transported for assembly on-site. These walls come in a variety of materials, including concrete, wood, and metal, and their production streamlines the construction process, reducing time and labor costs significantly. According to a report by the National Institute of Building Sciences, incorporating prefabricated elements can cut construction time by up to 50%, which is particularly beneficial in today's fast-paced market where project timelines are increasingly tight.

One of the standout benefits of prefabricated walls is their improved quality control. As they are produced in a factory setting, there is less exposure to environmental variables that can compromise construction quality. A report from McKinsey & Company suggests that standardizing construction processes through prefabrication can reduce defects by as much as 70%, enhancing both the durability and performance of buildings. Additionally, the sustainability aspect cannot be overlooked; prefabricated walls generate less waste during production and often use eco-friendly materials, aligning with the industry's shift toward greener practices. As the construction landscape evolves, understanding these benefits empowers builders and developers to make informed decisions about their projects.

Key Materials Used in Prefab Wall Construction and Their Impact

When selecting prefab walls for your construction project, understanding the key materials used in their construction is crucial. The most common materials include metal, wood, and concrete. Each material has distinct properties that can significantly influence the project's sustainability, cost-efficiency, and overall performance. For instance, concrete panels provide excellent insulation and durability, making them ideal for energy-efficient buildings. On the other hand, wood panels offer flexibility and ease of installation, which can expedite the construction timeline.

Tips for choosing the right materials: Assess the environmental impact and energy efficiency of the options available. For those aiming for a sustainable project, consider using recycled or environmentally friendly materials. Additionally, evaluate the climate of the construction site, as this will dictate the resilience needed from your wall materials. It’s also beneficial to consult with architects or construction experts who can provide tailored advice based on the project's specific requirements.

Incorporating advanced materials like insulated panels can also enhance thermal performance, reducing energy costs in the long term. This advancement allows building owners to enjoy significant savings while providing a comfortable living or working environment. Always keep in mind the project's timeline and budget, as some materials may carry higher upfront costs but yield long-term benefits. By weighing these factors, you can ensure a successful prefab wall selection that aligns with your construction objectives.

Evaluating Structural Integrity: Design Standards and Regulations

When selecting prefabricated walls for your construction project, evaluating structural integrity is paramount. Understanding design standards and regulations that govern prefabricated construction is essential for ensuring the safety and durability of your structure. Each project must comply with local building codes, which may dictate specific requirements regarding materials, load-bearing capacities, and wind resistance. Familiarizing yourself with these regulations at the outset can prevent costly modifications later in the project.

In addition to local regulations, it is crucial to assess the material specifications of the prefabricated walls. High-quality materials should meet or exceed established industry standards for strength and performance. Factors such as seismic resistance, fire ratings, and thermal efficiency play a significant role in evaluating the overall integrity of the walls. Consulting with professionals who specialize in prefabricated construction can provide valuable insights into the best choices for your project, helping to ensure compliance with all applicable standards while also meeting your design and functional needs.

Evaluating Structural Integrity of Pre Fab Walls

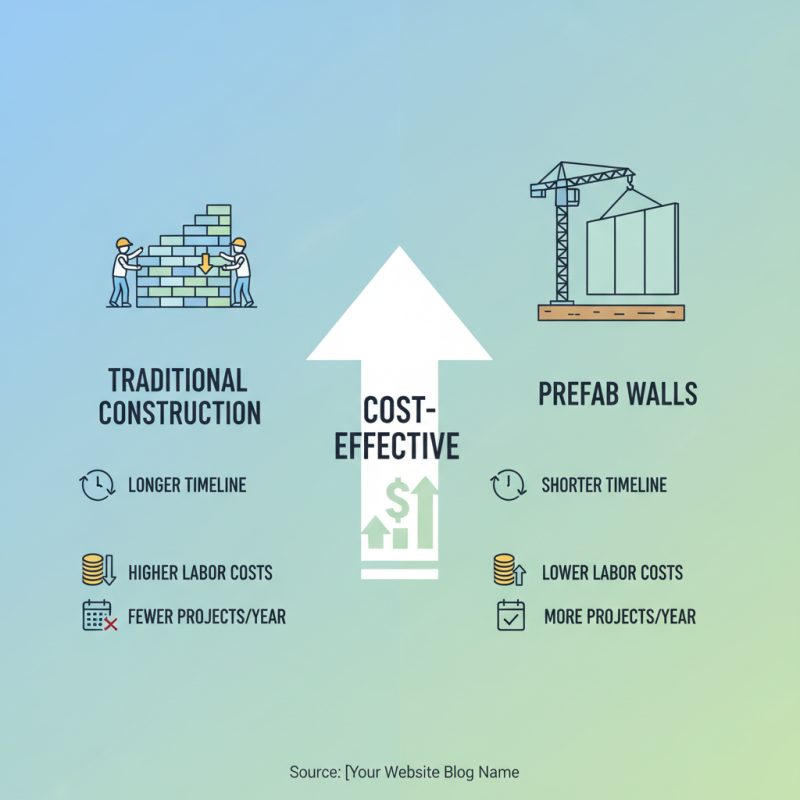

Cost Analysis: Comparing Prefab Walls to Traditional Construction Methods

When evaluating the cost-effectiveness of prefab walls versus traditional construction methods, one must consider various factors that influence overall expenses. Prefab walls often lead to significant savings in labor costs due to their quick installation. Since these walls are manufactured off-site and then delivered ready for assembly, construction time is notably reduced. This decrease in project duration can translate into lower onsite labor expenses and can also allow contractors to take on multiple projects simultaneously, maximizing profitability.

On the flip side, traditional construction methods typically involve a longer timeline due to the numerous stages of assembly and drying times of materials. Labor is generally less efficient, as construction workers manually assemble components on-site, which can lead to increased costs related to overtime pay and potential delays. Furthermore, the unexpected expenses that can arise from weather delays or on-site accidents are generally higher in traditional methods compared to the controlled environment of factory production for prefab walls. Thus, when conducting a cost analysis, it becomes clear that while the initial investment in prefab technology may seem higher, the long-term benefits and savings often outweigh those associated with traditional construction techniques.

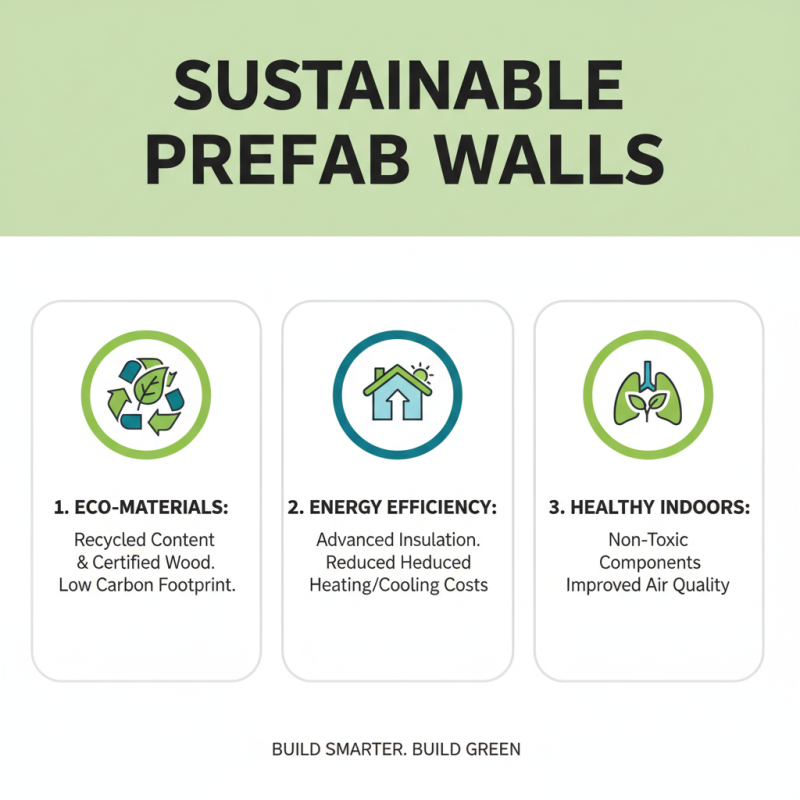

Sustainability Considerations in Prefab Wall Selection for Projects

Sustainability is a crucial factor in selecting prefab walls for your construction project. When evaluating options, consider materials that have low environmental impact throughout their lifecycle. Options such as recycled materials or sustainably sourced timber not only reduce the carbon footprint but also contribute to a healthier indoor environment. Additionally, opting for insulation that maximizes energy efficiency can lead to significant reductions in energy consumption for heating and cooling, impacting both operational costs and environmental sustainability.

Another important aspect is the manufacturing process of prefab walls. Seeking suppliers who utilize eco-friendly production methods can enhance the overall sustainability of your project. Look for companies that prioritize renewable energy sources and minimize waste during the manufacturing process. Furthermore, consider the ability of prefab walls to be dismantled and repurposed at the end of their lifecycle, as this feature supports a circular economy and reduces landfill waste. By focusing on these sustainability considerations, you can make informed choices that not only meet your project’s needs but also align with broader environmental goals.

Related Posts

-

Top Benefits of Pre Built Wall Panels for Your 2025 Construction Projects

-

How to Choose the Best Premade Walls for Your Next Construction Project

-

What is Prefabricated Wall Panels and How Do They Benefit Construction Projects

-

Top 10 Tips for Choosing Framing Lumber: A Complete Buying Guide

-

What Are Raised Wall Panels? Benefits, Types, and Installation Tips Explained

-

How to Use Prefabricated Interior Wall Panels for Efficient Home Design