- RESIDENTIAL CONSTRUCTION

- COMMERCIAL CONSTRUCTION

- HOME IMPROVEMENT

- Products

- Framing Lumber & Sheathing

- Exterior Siding

- Doors

- Molding

- Windows

- Drywall

- Roofing

- Insulation

- Roof Trusses

- Floor Trusses

- Engineered Wood Products

- Masonry & Concrete

- Decks

- Hand & Power Tools

- Hardware

- Paint & Stain

- Plumbing

- Heating & Cooling

- Lawn & Garden

- Lighting & Electrical

- Storage & Organization

- Kitchen Cabinets

- Flooring

- Fencing

- Mobile Home & RV Supply

- Services

- Home Inspiration

- Current Ads

- Build Rewards

- Service Directory

- Products

- REQUEST A QUOTE

- BLOG

- CONTACT

- ACCOUNT SETUP

- ABOUT

How to Choose the Best Premade Walls for Your Next Construction Project

In recent years, the construction industry has witnessed a significant shift toward the adoption of prefabrication techniques, with premade walls at the forefront of this evolution. According to a report by MarketsandMarkets, the global market for prefabricated building components is projected to reach $116.4 billion by 2025, demonstrating a growing recognition of the efficiency and sustainability these structures offer. Premade walls not only expedite the construction process but also enhance quality control and reduce waste, aligning with the heightened emphasis on sustainable building practices.

When considering premade walls for your next construction project, it is crucial to evaluate several factors, including material quality, design flexibility, and installation efficiency. Research from McKinsey indicates that companies implementing modular construction methods can reduce project timelines by up to 50%, highlighting the urgency for industry professionals to harness these innovations. As demand for rapid construction solutions intensifies, selecting the best premade walls could become a pivotal element in delivering projects that meet both budgetary constraints and client expectations. Understanding how to navigate this growing market will empower builders to achieve their project goals with greater agility and effectiveness.

Understanding Premade Walls: Types and Benefits

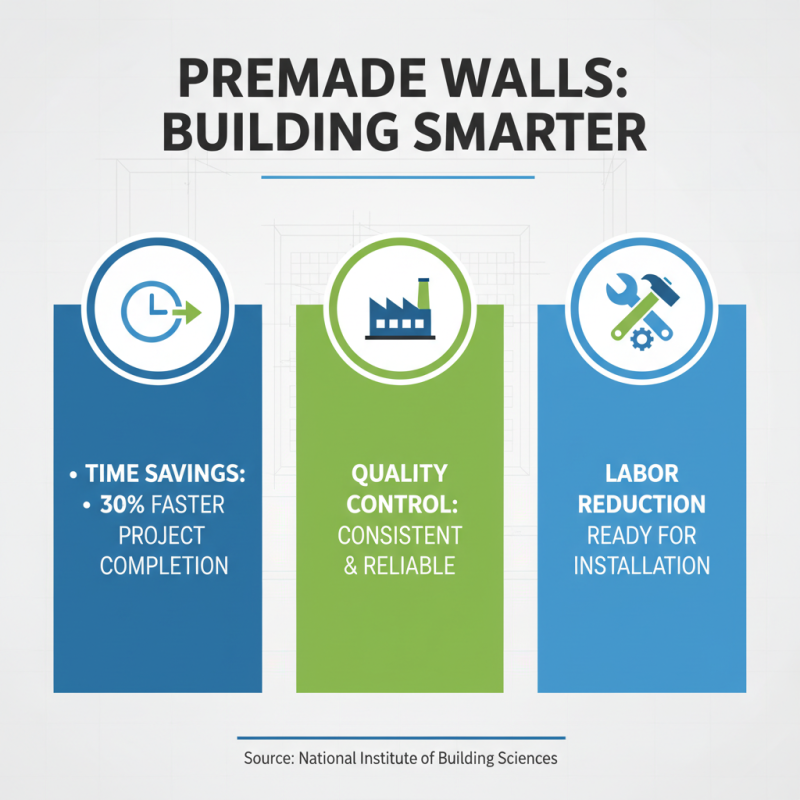

Premade walls have gained popularity in the construction industry due to their efficiency and versatility. These walls are typically manufactured off-site and delivered ready for installation, significantly reducing on-site labor time. According to a report from the National Institute of Building Sciences, using premade wall systems can cut project timelines by up to 30%, which is beneficial for projects with tight schedules. Additionally, the controlled manufacturing environment allows for better quality control and consistent performance compared to traditional on-site construction methods.

There are several types of premade walls, including panelized, modular, and tilt-up walls, each offering different benefits depending on the construction requirements. For instance, modular walls provide quicker assembly and are ideal for projects that require architectural flexibility. A study from the Modular Building Institute highlights that modular construction can result in an overall energy savings of 10-20% due to enhanced insulation properties and reduced waste during construction. Furthermore, premade walls can also contribute to sustainability efforts, as many manufacturers are increasingly using eco-friendly materials and practices in their production processes, aligning with the industry's goal to minimize environmental impact.

Key Factors to Consider When Selecting Premade Walls

When selecting premade walls for your construction project, several key factors should be carefully considered to ensure you make the best choice for your needs. First and foremost, evaluate the material of the premade walls. Different materials, such as concrete, wood, or steel, offer distinct advantages in terms of durability, insulation properties, and cost efficiency. Understanding the environmental conditions of your project site can help you determine which material will provide the most suitable performance and longevity.

Another critical factor is the design and customization options available. Depending on the specific requirements of your project, you may need walls that can accommodate electrical installations, plumbing, or unique architectural features. Ensure that the manufacturer offers flexibility in design, allowing for modifications that cater to your project’s aesthetic and functional needs. Finally, consider the ease of installation and transportation. Premade walls that are lightweight yet sturdy can significantly reduce labor costs and construction time, making them a practical choice for many builders. By weighing these factors, you can ensure that your selection of premade walls aligns with your project's goals and budget.

Comparing Materials: Wood, Steel, and Concrete Options

When it comes to choosing premade walls for your construction project, the material selection plays a crucial role in determining the wall's performance, durability, and overall impact on the project. The three most common materials for premade walls are wood, steel, and concrete, each with its unique set of advantages and drawbacks.

Wood offers a lightweight, aesthetically pleasing option that is often easier and faster to work with. It provides good insulation properties and can be treated for improved resistance to weather and pests. However, wood may require more maintenance over time and could be vulnerable to rot or fire hazards in certain environments.

On the other hand, steel walls provide exceptional strength and durability, making them ideal for large commercial structures where stability is key. Steel is resistant to many environmental stresses and pests, making it a low-maintenance choice. However, it can be more expensive and may require additional insulation to ensure energy efficiency, as steel conducts heat and cold more readily than wood or concrete.

Concrete, while the heaviest option, offers unparalleled fire resistance and sound insulation, making it a go-to material for structures that prioritize safety and noise control. It is highly durable and can withstand severe weather conditions, but its installation process can be more labor-intensive and costly. Each material has its pros and cons, and the choice should align with project specifications, budget constraints, and the desired aesthetic outcome.

Comparative Analysis of Premade Wall Materials

This chart compares the thermal insulation, fire resistance, and cost of different premade wall materials: Wood, Steel, and Concrete.

Evaluating Cost Efficiency and Budget Constraints

When it comes to selecting premade walls for your next construction project, evaluating cost efficiency should be a top priority. The initial cost of materials, labor, and installation can vary significantly, making it crucial to assess the overall financial implications of your choices. To ensure that you stay within budget constraints, begin by gathering quotes from multiple suppliers while considering not just the upfront costs but also the long-term durability and maintenance requirements of the walls. Cheap materials might save money initially, but they could lead to higher expenses if replacement or repairs are needed sooner than expected.

Moreover, look into the potential for energy savings that certain premade wall options can provide. Insulated panels, for instance, may have a higher upfront cost but can significantly reduce heating and cooling expenses over time. Evaluate the total cost of ownership through energy efficiency to determine what materials will yield the best return on investment. By carefully balancing initial costs against future expenses, you can make informed decisions that align with both financial and project goals, ensuring that your construction project remains economically viable.

How to Choose the Best Premade Walls for Your Next Construction Project - Evaluating Cost Efficiency and Budget Constraints

| Wall Type | Material | Cost per Unit ($) | Installation Time (hrs) | Insulation Rating (R-value) | Durability (Years) |

|---|---|---|---|---|---|

| Concrete Panel | Concrete | 50 | 8 | 4 | 40 |

| Lightweight Steel Frame | Steel | 75 | 6 | 5 | 30 |

| Wood Panels | Wood | 40 | 5 | 3 | 20 |

| Fiber Cement Board | Cement | 65 | 7 | 6 | 35 |

| Insulated Concrete Forms | Polyurethane & Concrete | 85 | 10 | 7 | 50 |

Importance of Compliance with Building Regulations and Standards

When selecting premade walls for your construction project, ensuring compliance with building regulations and standards is paramount. These regulations are established to guarantee safety, structural integrity, and environmental sustainability. Builders and architects must familiarize themselves with local laws and codes that govern the materials and construction methods used. Choosing walls that comply not only helps in avoiding legal repercussions but also mitigates risks associated with structural failures and safety hazards.

Furthermore, adherence to these regulations facilitates smoother inspections and approvals throughout the construction process. Non-compliance can lead to costly delays, rework, or even the disqualification of the entire project. It is critical to evaluate the specifications of premade walls against relevant standards, such as fire resistance, insulation efficiency, and load-bearing capabilities. By prioritizing compliance, construction professionals can enhance the overall quality of their projects while promoting a safer environment for occupants and the surrounding community.