- RESIDENTIAL CONSTRUCTION

- COMMERCIAL CONSTRUCTION

- HOME IMPROVEMENT

- Products

- Framing Lumber & Sheathing

- Exterior Siding

- Doors

- Molding

- Windows

- Drywall

- Roofing

- Insulation

- Roof Trusses

- Floor Trusses

- Engineered Wood Products

- Masonry & Concrete

- Decks

- Hand & Power Tools

- Hardware

- Paint & Stain

- Plumbing

- Heating & Cooling

- Lawn & Garden

- Lighting & Electrical

- Storage & Organization

- Kitchen Cabinets

- Flooring

- Fencing

- Mobile Home & RV Supply

- Services

- Home Inspiration

- Current Ads

- Build Rewards

- Service Directory

- Products

- REQUEST A QUOTE

- BLOG

- CONTACT

- ACCOUNT SETUP

- ABOUT

What is Prefabricated Wall Panels and How Do They Benefit Construction Projects

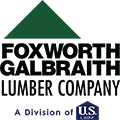

Prefabricated wall panels have emerged as a revolutionary solution in the construction industry, offering a range of advantages that enhance efficiency and reduce costs. These panels, manufactured off-site and then transported to construction sites, streamline the building process and significantly cut down on construction time. By utilizing prefabricated wall panels, builders can benefit from improved quality control, as these components are produced in a controlled environment, ensuring consistency and durability.

The integration of prefabricated wall panels into construction projects not only speeds up the building process but also minimizes on-site labor requirements. This innovation allows for a more organized and safer work environment, as much of the assembly is completed away from the construction site. Furthermore, with the ability to customize designs and finishes during the manufacturing process, prefabricated wall panels offer builders flexibility to meet specific project demands while adhering to modern architectural standards.

In summary, the advantages of prefabricated wall panels include enhanced construction efficiency, reduced labor costs, and the potential for high-quality finishes and designs. As the construction industry continues to evolve, the adoption of prefabricated wall panels represents a significant shift towards more sustainable and cost-effective building practices, benefiting both contractors and clients alike.

Definition of Prefabricated Wall Panels in Construction

Prefabricated wall panels are construction elements manufactured off-site in controlled environments before being transported to the building site for assembly. This innovative approach enables the production of complete wall sections that include insulation, electrical wiring, and finishes, reducing labor time and on-site construction activities. According to a report by McKinsey & Company, modular construction, which includes the use of prefabricated panels, can decrease project delivery times by up to 50% and reduce costs by 20%. The integration of prefabricated wall panels significantly enhances construction efficiency and quality, promoting a streamlined workflow and minimizing material waste.

When considering the implementation of prefabricated wall panels in your projects, it is essential to understand their benefits fully. For example, they not only expedite project timelines but also improve energy efficiency in buildings, with some panels reaching up to R-value 30 for insulation performance, as noted in industry reports. Additionally, prefabricated solutions contribute to safer work environments by decreasing the need for prolonged on-site labor, thus lowering the risk of accidents.

**Tips:** Before selecting a manufacturer for your prefabricated wall panels, ensure to evaluate their certifications and previous project outcomes. Collaborating with architects who are experienced with modular designs can also maximize the benefits of prefabrication, ensuring that your building adheres to local codes while achieving optimal energy performance.

Benefits of Prefabricated Wall Panels in Construction Projects

This chart illustrates the key benefits of using prefabricated wall panels in construction projects, highlighting their impact on cost savings, construction speed, quality control, waste reduction, and safety measures.

Types of Prefabricated Wall Panels and Their Materials

Prefabricated wall panels are a popular choice in modern construction, offering a range of materials and types that cater to various building needs. Common types include concrete panels, wood panels, and steel-framed panels. Concrete panels are favored for their durability and structural integrity, making them ideal for commercial and industrial applications. On the other hand, wood panels tend to provide a natural aesthetic and excellent insulation properties, making them a popular option for residential buildings. Steel-framed panels are known for their strength and versatility, often used in large-scale projects where stability and weight considerations are crucial.

When choosing the right type of prefabricated wall panel, consider the project's specific requirements. For instance, if insulation is a priority, opt for panels with high thermal resistance. Additionally, evaluating the local climate can help determine which materials will perform best over time.

Tips: Always consult with a structural engineer to ensure that the selected panels meet building codes and regulations. Another useful suggestion is to collaborate closely with manufacturers during the design phase to customize panels that meet unique project specifications, ultimately improving efficiency and reducing waste during construction.

What is Prefabricated Wall Panels and How Do They Benefit Construction Projects

| Type of Prefabricated Wall Panel | Material Used | Benefits | Typical Applications |

|---|---|---|---|

| Structural Insulated Panels (SIPs) | Polyurethane or Polystyrene core with OSB or plywood sheathing | High energy efficiency, quick assembly, and strong structural integrity | Residential and commercial buildings |

| Precast Concrete Panels | Reinforced concrete | Durability, fire resistance, and minimal maintenance | High-rise buildings, warehouses, and industrial facilities |

| Metal Wall Panels | Aluminum or steel | Lightweight, corrosion resistance, and aesthetic appeal | Commercial buildings, factories, and storage units |

| Wood Frame Panels | Wood framing with sheathing | Sustainability, good insulation, and ease of construction | Residential homes and light commercial structures |

Advantages of Using Prefabricated Wall Panels in Building Projects

Prefabricated wall panels are revolutionizing the construction industry by offering significant benefits over traditional building methods. One of the primary advantages is the speed of construction. Since the panels are manufactured off-site, they can be assembled quickly on-site, drastically reducing the time required to erect a building. This accelerated timeline not only helps meet project deadlines but also minimizes labor costs and reduces the overall time to market for developers.

Another key benefit of using prefabricated wall panels is the enhanced quality control they provide. Manufactured in a controlled environment, these panels undergo stringent quality checks, ensuring consistent performance and durability. This results in fewer defects compared to on-site construction, leading to improved safety and structural integrity. Additionally, prefabrication encourages material efficiency, as it minimizes waste during the manufacturing process. This environmentally friendly approach aligns with sustainable building practices, making prefabricated wall panels an attractive option for eco-conscious projects.

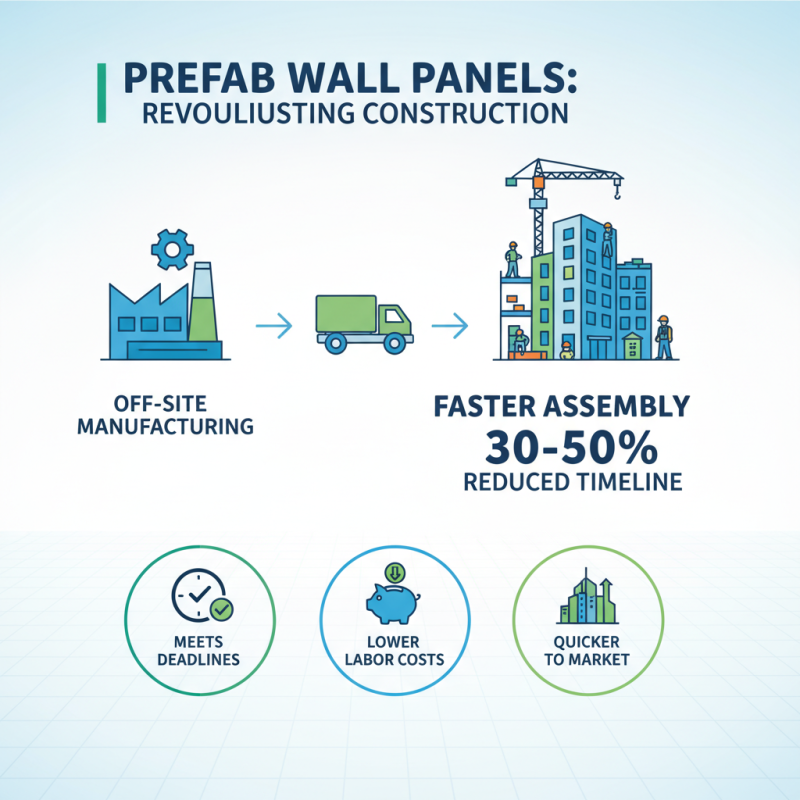

Installation Process of Prefabricated Wall Panels on Site

The installation process of prefabricated wall panels on site is a crucial stage in modern construction that can streamline project timelines and enhance quality. Typically, this process begins with site preparation, ensuring that the foundation and any necessary framing are ready to receive the panels. Once the site is adequately prepared, delivery logistics come into play, where the panels, which are manufactured off-site, are transported to the construction site in a pre-cut and ready-to-install format.

Upon arrival, skilled workers begin the installation by carefully unloading the panels, ensuring that they are not damaged in the process. The panels are then lifted into position, often utilizing cranes or other lifting equipment, and are aligned to fit precisely with the established foundation and structural framing. This alignment is crucial as it not only affects the aesthetic appeal of the building but also its structural integrity. Once in place, the panels are secured with fasteners, and any gaps are sealed to ensure thermal efficiency and weather resistance. This method not only accelerates the construction process but also significantly reduces labor costs, making prefabricated wall panels an attractive option for builders seeking efficiency without compromising quality.

Cost Comparison: Prefabricated Wall Panels vs. Traditional Construction Methods

Prefabricated wall panels have emerged as a transformative component in the construction industry, particularly when comparing their costs to traditional construction methods. According to a report by the National Institute of Standards and Technology (NIST), prefabricated components can reduce construction costs by up to 20% due to their streamlined manufacturing processes and reduced labor requirements. This is largely because prefabricated panels are constructed in controlled factory environments, allowing for faster assembly on-site and minimizing delays caused by weather or site conditions.

In addition, a study from McKinsey & Company indicates that the construction sector could save approximately $1.6 trillion annually if it adopts modern building methods, such as prefabrication. This highlights the economic advantage of prefabricated wall panels, not only in upfront costs but also in long-term savings associated with reduced labor costs and shorter project completion times. The panelized systems also allow for easier scalability, accommodating changes in project design without significant financial ramifications. As construction projects continue to seek efficiencies, the cost benefits of prefabricated wall panels over traditional methods are becoming increasingly evident, positioning them as a favorable choice for developers and contractors alike.

Related Posts

-

Top Benefits of Pre Built Wall Panels for Your 2025 Construction Projects

-

How to Choose the Best Premade Walls for Your Next Construction Project

-

Top 10 Tips for Choosing Framing Lumber: A Complete Buying Guide

-

How to Use Prefabricated Interior Wall Panels for Efficient Home Design

-

What Are Raised Wall Panels? Benefits, Types, and Installation Tips Explained

-

What is Flat Panel Wainscoting and How Can It Transform Your Home