- RESIDENTIAL CONSTRUCTION

- COMMERCIAL CONSTRUCTION

- HOME IMPROVEMENT

- Products

- Framing Lumber & Sheathing

- Exterior Siding

- Doors

- Molding

- Windows

- Drywall

- Roofing

- Insulation

- Roof Trusses

- Floor Trusses

- Engineered Wood Products

- Masonry & Concrete

- Decks

- Hand & Power Tools

- Hardware

- Paint & Stain

- Plumbing

- Heating & Cooling

- Lawn & Garden

- Lighting & Electrical

- Storage & Organization

- Kitchen Cabinets

- Flooring

- Fencing

- Mobile Home & RV Supply

- Services

- Home Inspiration

- Current Ads

- Build Rewards

- Service Directory

- Products

- REQUEST A QUOTE

- BLOG

- CONTACT

- ACCOUNT SETUP

- ABOUT

Top 10 Tips for Choosing Framing Lumber: A Complete Buying Guide

When embarking on a construction or renovation project, one of the most crucial decisions you’ll make is selecting the right framing lumber. This essential material serves as the backbone of your structure, influencing both its strength and overall aesthetic appeal. With a myriad of choices available in the market, understanding how to choose the perfect framing lumber can be overwhelming. This comprehensive buying guide aims to simplify that process by providing you with top tips to consider.

From assessing your project's specific needs to evaluating the quality of various lumber types, each decision plays a vital role in ensuring your structure is durable and sustainable. Whether you are a seasoned contractor or a DIY enthusiast, having a solid grasp of the factors that impact framing lumber selection will not only save you time and money but also contribute to the longevity of your project. Join us as we explore the key considerations you need to keep in mind while navigating the world of framing lumber.

Understanding Different Types of Framing Lumber Available on the Market

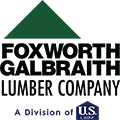

When selecting framing lumber, it's essential to understand the various types available, each with its specific characteristics and applications. The most common types of framing lumber are softwoods such as pine, fir, and spruce, which are widely used in residential construction due to their availability and relatively low cost. According to the Wood Products Council, approximately 88% of new homes in the U.S. utilize softwood lumber products for framing, highlighting their popularity among builders. These species are favored for their strength-to-weight ratio and ease of handling, making them ideal for structural applications.

In addition to softwoods, engineered wood products like laminated veneer lumber (LVL) and i-beams are increasingly being used in framing. The American Forest & Paper Association reported that the demand for engineered wood has grown by over 15% in the past five years, driven by their ability to span longer distances and reduce waste during construction. This trend reflects a shift toward more sustainable building practices, as engineered wood can be produced using smaller, fast-growing trees, thus promoting forest conservation. Understanding these options allows builders to make informed decisions based on structural requirements and environmental considerations.

Evaluating the Quality and Grading of Lumber for Framing Projects

When embarking on framing projects, the quality and grading of lumber play a vital role in ensuring structural integrity and longevity. According to the American Wood Council, the grading of lumber is based on its appearance and strength characteristics, which directly affect its suitability for framing. Higher grades, such as Select Structural and No. 1, are generally recommended for load-bearing applications, while lower grades may be acceptable for non-structural elements. It's crucial for builders and DIY enthusiasts alike to understand these distinctions to avoid costly repairs down the line.

One of the first tips for selecting framing lumber is to inspect the moisture content. Lumber that has a high moisture content can lead to warping, cracking, and other issues once the structure is complete. Ideally, framing lumber should have a moisture content of 19% or lower, according to the National Association of Home Builders. Furthermore, always check for visible imperfections such as knots, checks, or splits, which can compromise its performance. Opting for straight and uniform boards will enhance the overall effectiveness of your framing project.

Lastly, don’t overlook the importance of sourcing materials from reputable suppliers who provide documentation of their lumber’s grading. Understanding the grading system—such as the differences between Common and Select grades—can give you a better idea of the material's anticipated performance. As reported by the USDA Forest Service, selecting high-quality lumber not only improves safety but also supports sustainable practices within the forestry industry. Engaging with reliable resources and taking the time to evaluate your options will contribute significantly to the success of your framing endeavors.

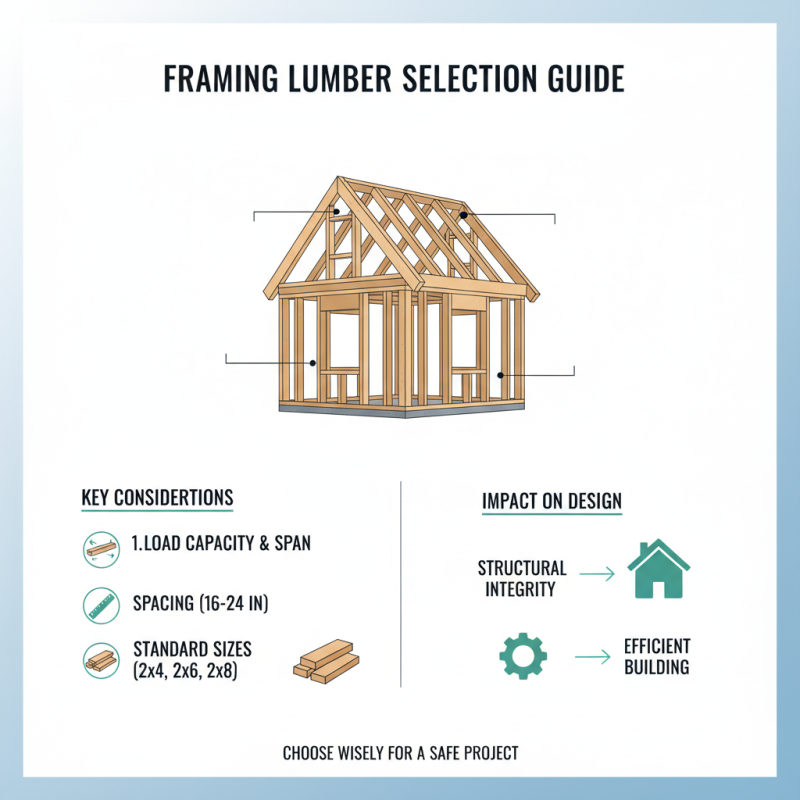

Selecting the Right Size and Dimensions for Your Framing Needs

When selecting framing lumber, accurately determining the right size and dimensions is crucial for ensuring the structural integrity of your project. Begin by assessing the specific requirements of your construction, including the load-bearing capacities and spans that your framing will need to support. It’s important to choose lumber that matches the spacing between your studs, joists, or rafters, typically ranging from 16 to 24 inches apart. Standard sizes are readily available, such as 2x4, 2x6, and 2x8, but understanding how these dimensions impact the overall design is key to safe and efficient building.

In addition to standard sizes, consider the thickness of the lumber in relation to the type of framing you're undertaking. Thicker lumber may be necessary for heavy loads or longer spans, while lighter framing could allow for more flexibility in dimension choices. Moreover, pay attention to local building codes, which may dictate specific requirements for dimensions and spacing. Ultimately, taking the time to select the appropriate size and dimensions for your framing needs not only enhances the durability of your structure but also contributes to the overall efficiency of the building process.

Considering Environmental Impact and Sustainability When Choosing Lumber

When selecting framing lumber for your construction projects, it's essential to consider the environmental impact and sustainability of your choices. The lumber industry often has significant implications for forests and ecosystems. Opting for sustainably sourced lumber, such as those certified by organizations that promote responsible forestry practices, can help mitigate deforestation and promote biodiversity. This means choosing products that are harvested in a way that maintains the ecological balance, protecting not just the trees but also the wildlife habitats that depend on these forests.

Moreover, the processing and transportation of lumber can contribute to carbon emissions. Therefore, selecting locally sourced materials can further reduce your carbon footprint while supporting the local economy. Additionally, look for lumber that incorporates recycled content or reclaimed wood. These options not only reduce waste but also minimize the demand for virgin forest resources. Making informed decisions about the origins and sustainability practices associated with your framing lumber is crucial for reducing your environmental impact and promoting a greener building industry.

Top 10 Tips for Choosing Framing Lumber: A Complete Buying Guide - Considering Environmental Impact and Sustainability When Choosing Lumber

| Tip No. | Tip Description | Environmental Benefits | Sustainability Rating |

|---|---|---|---|

| 1 | Choose certified wood products | Supports sustainable forestry | High |

| 2 | Opt for reclaimed lumber | Reduces waste and resource use | Very High |

| 3 | Consider local sources | Lowers transportation emissions | High |

| 4 | Select durable species | Longer lifespan reduces waste | Medium |

| 5 | Inspect for chemical treatments | Minimizes toxins in the environment | High |

| 6 | Evaluate energy efficiency of production | Lower carbon footprint | Medium |

| 7 | Research sustainable practices of suppliers | Supports ethical sourcing | High |

| 8 | Look for environmentally friendly certifications | Assured eco-friendly standards | Very High |

| 9 | Prioritize using wood from healthy forests | Contributes to forest conservation | Very High |

| 10 | Stay informed on lumber alternatives | Find more sustainable options | Medium |

Tips for Comparing Prices and Sourcing Lumber from Local Suppliers

When it comes to sourcing framing lumber, understanding the pricing landscape and local suppliers' reliability can make a significant difference in your project budget and quality. According to the U.S. Forest Service, framing lumber prices have varied greatly over the years, often influenced by economic trends, demand, and supply chain disruptions. This volatility highlights the importance of diligently comparing prices before making a purchase.

One effective tip is to gather quotes from multiple local suppliers. This will not only give you a better idea of the prevailing market rates but also help you establish a relationship with your suppliers, which can be advantageous in the long run. Additionally, consider visiting lumber yards to inspect the quality firsthand, as photographs or online descriptions may not always accurately portray the condition of the wood.

Another strategy is to keep an eye on seasonal trends in lumber pricing. Research indicates that prices often rise in spring when construction activity increases. By timing your purchases strategically during off-peak seasons, you can potentially save a substantial amount. Always be mindful of delivery costs, which can vary between suppliers and significantly impact your total expense. Comparing both material prices and the associated logistics will equip you to make informed purchasing decisions that align with your budgetary constraints.